RTM Series Mill

Constructions specifications

Suitable for all material with a humidity of less than 2% and a material hardness of max.

4 (Mohs scale), suitable for virtually all sectors where very fine grinding is required: minerals, pharmaceutical, chemical, food, etc.

Product particle fineness d97, 8 ÷ 120 micron.

Special application for toxic waste smoke treatment.

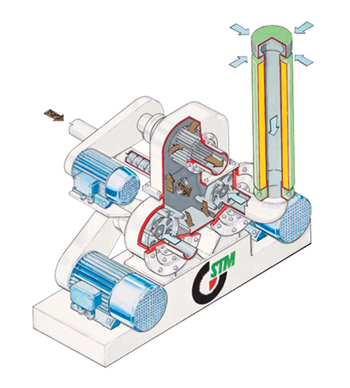

Operational principle

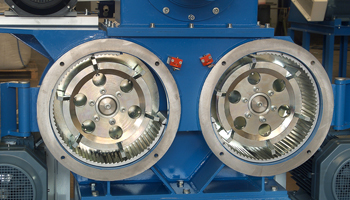

The grinding process is achieved by the impact of the material particles against the grinding track and against each other.

The grinding chamber is divided into two sections each with its own grinding disc.

The two discs are turning in different directions against each other thus generating the particle flow against the grinding track and against each other.

This grinding method results in an optimised energy efficiency.

Operational advantages

- Compact design, limited space requirement, easy installation.

- Minimum maintenance

- Reduced energy consumption due to the electronic operation control system

- Possibility to adjust the particle size at the control board even while the machine is running

- Fully automatic operation process

Generics machine data*

| RTM Size |

Total Installed Power | Total Absorbed Power | Capacity per hour | Raw Material | Fineness* | Air Capacity | Pressure | Dedusting filter | Noisiness |

|---|---|---|---|---|---|---|---|---|---|

| KW | KW | Range - kg/h | mc/h | mmH2O | mq | dBA | |||

| 300s | 17,5 | 15,8 | 10 ÷ 250 | < 10 mm | d.90 < 20µm d.50 < 5µm |

1.600,0 | 500,0 | 12,0 | < 75 |

| 400s | 44,5 | 40,1 | 40 ÷ 450 | < 10 mm | d.90 < 20µm d.50 < 5µm |

3.000,0 | 800,0 | 24,0 | < 75 |

| 600s | 101,0 | 90,9 | 100 ÷1000 | < 10 mm | d.90 < 20µm d.50 < 5µm |

5.000,0 | 800,0 | 30,0 | < 75 |

| 800s | 125,0 | 112,5 | 100 ÷1400 | < 10 mm | d.90 < 20µm d.50 < 5µm |

9.000,0 | 1.000,0 | 55,0 | < 75 |

| 1000s | 202,0 | 181,8 | 100 ÷ 1800 | < 10 mm | d.90 < 20µm d.50 < 5µm |

14.000,0 | 1.000,0 | 91,0 | < 75 |

* Data refer the use of CALCIUM CARBONATE